On sites operating heavy duty machinery, it is essential that safety measures are in place to prevent accidents. Operatives should be made aware of dangerous equipment and clear safety signage should be in place. Even experienced operatives can be injured by moving plant due to a variety of factors, including complacency and lack of communication between operatives and plant drivers.

See the examples below for how one site addressed this:

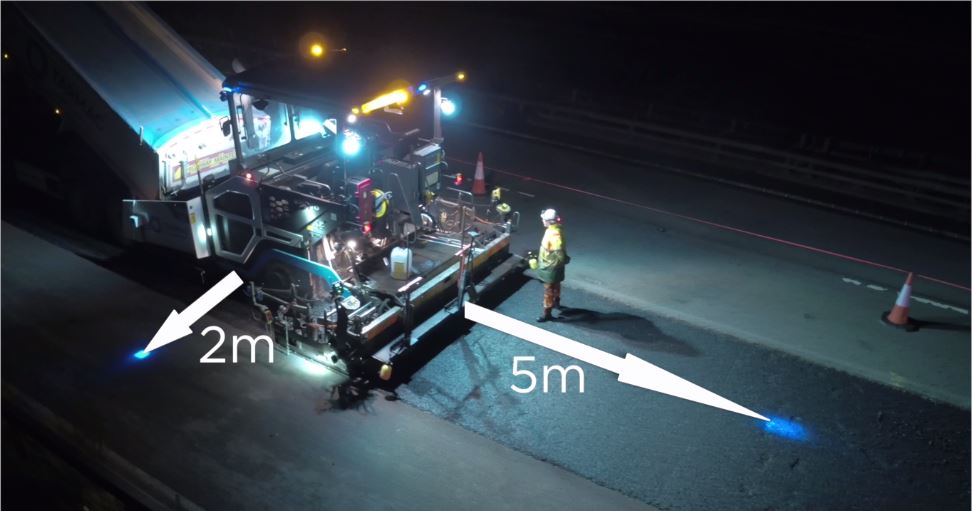

- Established a 5+2 initiative, encouraging operatives to maintain an exclusion zone of 2 metres to the side and 5 metres front and back of the machinery.

- The 5+2 initiative is clearly communicated on site through signs at the entry to site and vehicle stickers, and is featured in training procedures.

- Aware that much planing and surfacing works take place at night and highway sites can become very congested, the company took the policy further.

- They equipped the machinery with high-intensity blue lights that are directional on the road surface, clearly illuminating the 5+2 exclusion zone around the machinery.

- The lights will help operatives visualise the exclusion zone, therefore reducing the risk of accident.

By making the 5-2 exclusion zone policy visual through the use of blue lights, this site has made their health and safety policy clearer for everyone on site. In the 13 months preceding the establishment of the 5+2 policy, there were three serious accidents on sites involving a collision between operatives and plant; since the policy and the blue light initiative there have been no accidents of this kind. The system is being extended to other surfacing equipment and is steadily being adopted across the industry.

Monitor report. Tarmac Trading Ltd. Ultra Site. Nottinghamshire. February 2017.

Did you find this article helpful?

Please rate this article

Loading...