During the construction of the projects onsite mock up apartment, the contractor in collaboration with the subcontractor, identified that carrying out the stone installation in and around the bath unit was going to pose a risk to the operatives trying to manoeuvre the large format stone pieces above the bath, whilst standing within the curvature of the bath.

Another key risk identified was the potential damage to the high value Corian bath, which due to its manufacture process (casted) would not be able to be repaired onsite or in-situ.

They decided to approach this challenge by introducing a temporary working deck for the operatives to work from that could be used for part of the protection regime on site.

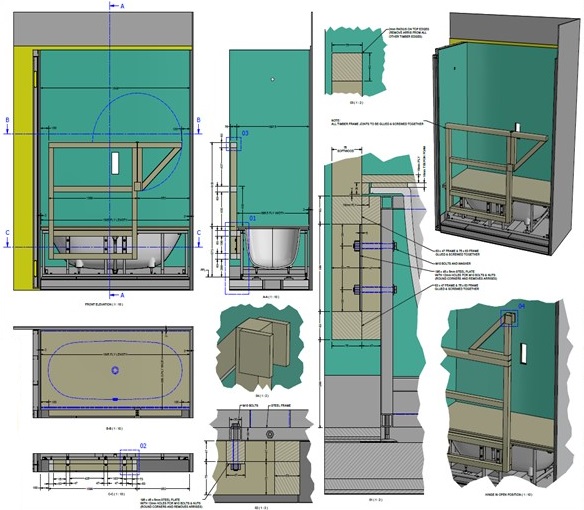

The working platform created a leading edge issue, which without a handrail protection could cause a potential for an operative to slip or fall. With 226 units to install the subcontractor designed a prototype handrail system and fitted this within the mock up bathroom which provided a safe means of access (lift gate), whilst providing full protection to operatives working from the platform.

A formal design and temporary works assessment was submitted, accompanied by calculations for approval. To ensure full protection is present from the outset of installation, the protection handrail system is manufactured and installed to the baths at the subcontractors offsite manufacturing facility.

When the bathrooms approach final completion, the handrail is removed and returned to the subcontractors offsite factory (when stillage’s are returned) where they are checked and reused on the follow on bath units.

Did you find this article helpful?

Please rate this article

Loading...