The Mace LSE Delivery Team along with Dornan Engineering and Ultra Sure Fire have excelled using their experience and knowledge of pre-fabrication and the associated health, safety and wellbeing benefits with a ground breaking innovation. This has been the first project to completely pre-fabricate sprinkler and dry riser installations.

The entire works have been 100% manufactured and developed off-site with the installation assembled without the use of a chop saw or threading machine. On 14 of 15 floors, the sprinkler installation is fully exposed. The sprinkler pipework installation includes a pre-sprayed architectural paint finish and pre-manufactured support brackets; the precise setting out complements the visual aspect of the project.

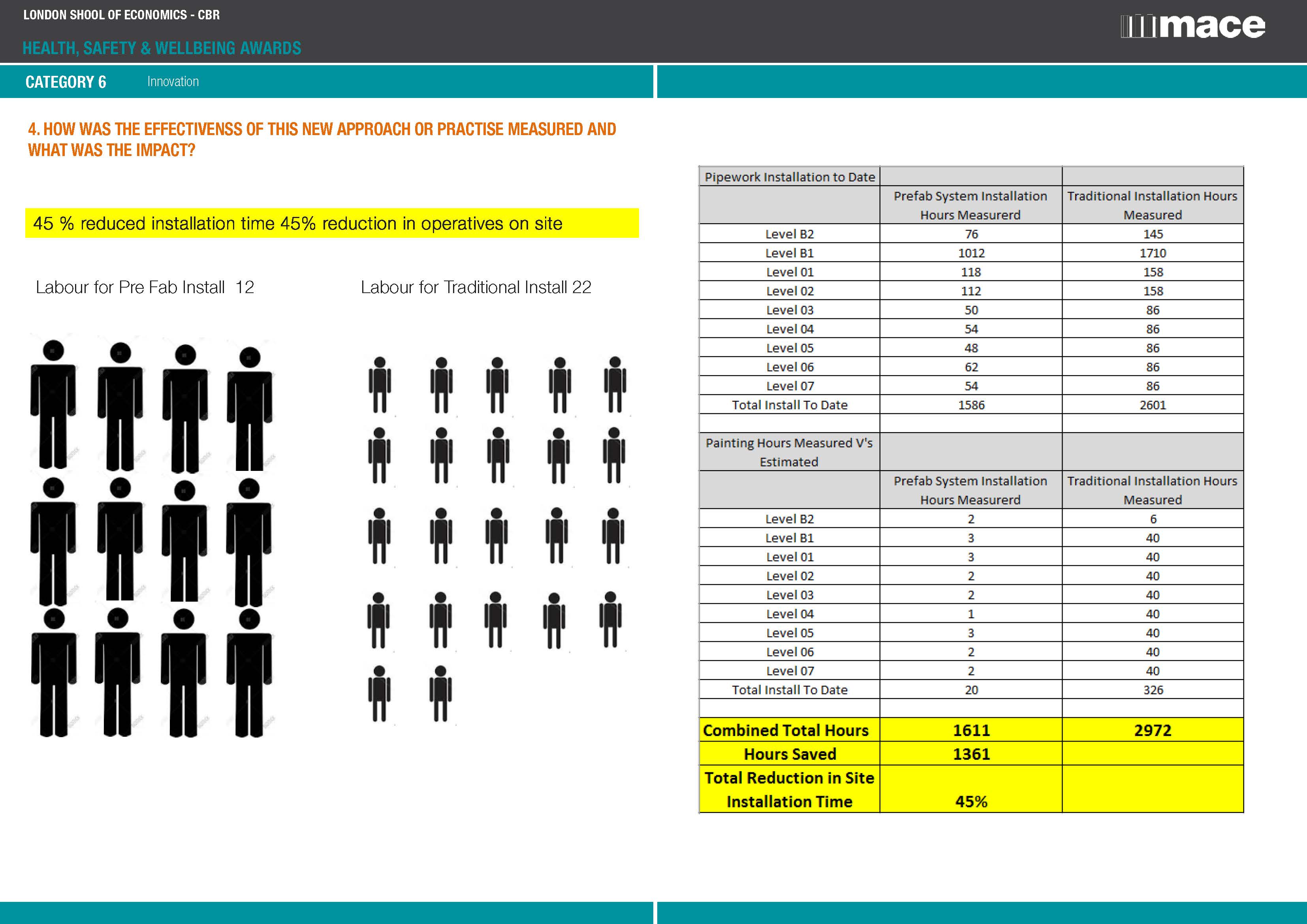

This has bought with it multiple benefits including less man hours on site and reduced deliveries which is an environmental victory in itself.

Lorna Edwards, Senior Architect said:

“The LSE Centre Buildings redevelopment, as with many other projects have exposed on floor MEPH services distribution throughout the scheme combined with ceiling suspended acoustic baffles. The detailed coordination and seamless setting out needed to achieve the high quality installation required for all the exposed services is made all the more challenging as the building has a splayed geometry which the services need to follow and a structural hollow core slab which limits fixing locations. The Mace team quickly reduced the level of upfront setting out and coordination involved combined with the finish of the sprinkler system lent itself perfectly for pre-fabrication and is reflected in the install.“

Did you find this article helpful?

Please rate this article

Loading...