After being asked by several leading construction companies about the need for a reduction in single use plastic, Lee Brothers set about the usual challenge of reducing areas like plastic cups, packing etc. However, one area that stood out where they could make a considerable difference was around single use signage and how they dispose of it.

After discussing with several companies, they have now introduced a range of 100% fully recyclable safety signage across all sizes from small entry level signs up to full 8ft x 4ft site hoarding boards.

This signage doesn’t use the old fashioned way of vinyl rolled onto material but instead uses direct to substrate printing. This process is more environmentally friendly, as it produces less waste and results in a longer lasting sign. Additionally, it also produces more vivid print detail.

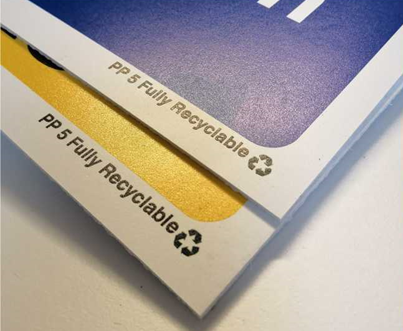

This new range of construction signs now include a PP05 logo and Recyclable Logo which identifies that these signs are fully recyclable and made of a material that has green credentials and environmental certificates.

The material is also biodegradable at landfill. However, this takes between 12-15 years which still means that the signage could get into the wrong hands and will not meet their client’s recycling policies.

So to combat this issue, Lee Brothers offer a full closed loop solution for their site safety signage. This means at the end of a project, their clients can simply call them to arrange a collection of their used signage.

Once the signs are collected, they are sent to a recycling centre and are eventually broken down to make new products like: ice scrapers, cutting boards and recycling bins.

Information supplied by Lee Brothers.

Did you find this article helpful?

Please rate this article

Loading...