The A64 Whitwell dual carriageway trunk road suffers from sub-standard horizontal and vertical geometry, leading to increased maintenance such as grass cutting being required each year, some years more than others depending on weather patterns.

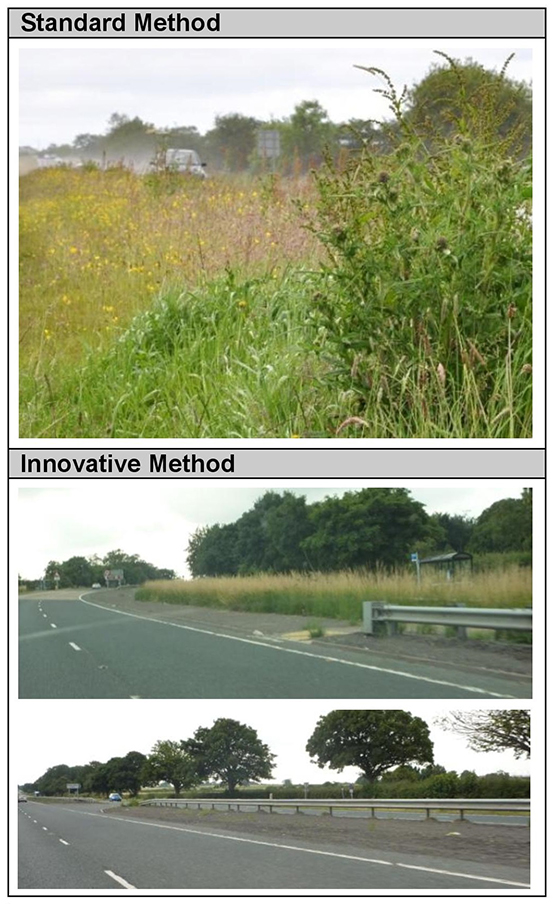

With designing for maintenance principles in mind, we developed a permeable verge hardening solution which removed the grass and topsoil from visibility splays and replaced this with T1000 terram geotextile and 150mm of planing material. This was applied to 12 locations in the central reserve and nearside verges. This permeable solution meant no expensive additional work to the existing drainage, which would have been required had a more conventional impermeable surface solution been adopted. The benefits of this solution are threefold:

- Improved road-user safety – reduced risk of accident through poor junction visibility

- Reduced network occupancy – we reduced the need for the maintenance provider to install expensive traffic management (lane closures) simply to undertake grass cutting operations, by 75%, ensuring increased network occupancy for road-users.

- Improved road worker safety – a 75% reduction in lane closures through verge hardening and proactive soft estate management is estimated to have saved 108 man-hours per year on this single stretch of the A64, where road workers are working on a live carriageway setting out traffic management.

So all in all, a simple, low cost effective construction solution that reduces long term risk, and is easily repeatable at other locations.

Did you find this article helpful?

Please rate this article

Loading...