As the construction industry moves toward net zero targets, accurate carbon measurement is becoming a critical part of responsible project delivery. With growing alignment to the UK Net Zero Carbon Building Standard and lifecycle assessment frameworks like EN 15978 and the RICS V2, contractors and developers are increasingly expected to measure, report, and reduce carbon emissions across a building’s lifecycle.

For many sites which already work on stringent low carbon requirements, this shift reflects a broader commitment to environmental responsibility and transparency. In particular, accurate calculation of embodied carbon at early project stages is an opportunity to demonstrate best practice and leadership in low-carbon construction.

Capturing A4 and A5 Emissions Responsibly

A key focus for whole-life carbon reporting is the accurate capture of emissions associated with product transport to site (A4) and construction/installation processes (A5) by sub-contractors. These stages can often be overlooked or inconsistently reported, particularly when Environmental Product Declarations (EPDs) are used alongside organisational data from site logistics and fuel use.

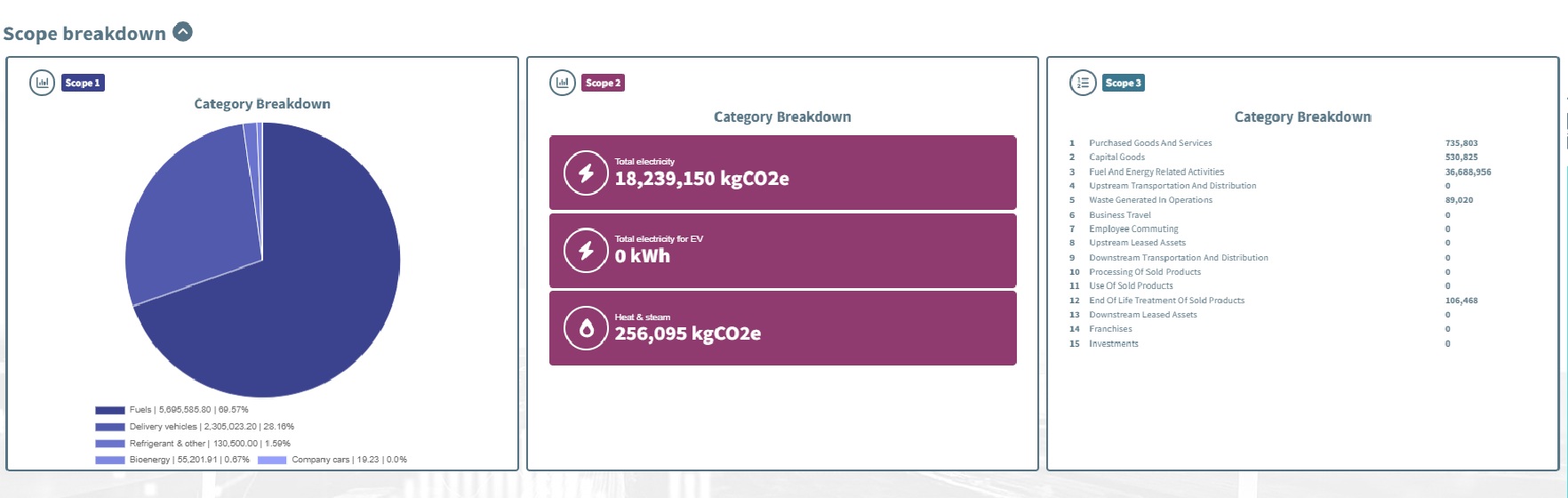

In one recent project, a full carbon calculation was carried out using an NZC Professional to support consistency and transparency. EPDs were used to populate baseline values, while transport distances, fuel types, and on-site energy use were gathered from project records. The platform allowed the team to report on A4 and A5 values which are reflective to the site location and requirements – a key feature in preventing double counting, especially when these emissions were already recorded in the sub contractors’ company-wide reporting tool – NZC Plus.

This level of control ensured that emissions were reported once and only once, ensuring the project carbon calculations start with accurate expectations around environmental integrity and clear documentation for the entire value chain involved in the project lifecycle.

Accuracy Through Process, Not Just Technology

While the digital platform streamlined the process, the accuracy of the calculation was not solely dependent on the software. Project teams still played a central role in validating data sources, setting system boundaries, and ensuring correct interpretation of EPDs. The platform acted as a structured workspace — enabling transparency, flagging data gaps, and providing version-controlled outputs — but decisions and assumptions remained under the team’s control.

Enabling More Considerate Sites

One of the clearest benefits reported by the team was the ability to respond quickly to carbon-related queries during site visits, audits, and stakeholder reviews. With data centralised and clearly documented, the team could demonstrate a robust, consistent and well-reasoned approach to carbon reporting.

Efficiency also improved. Manual spreadsheets, with their potential for errors and inconsistent formatting, were replaced by a more structured process, allowing the team to focus on decision-making and emissions reduction.

Conclusion

As carbon reporting becomes a standard expectation on UK construction sites, combining accurate methodology with digital support can strengthen both environmental outcomes and industry credibility. When used thoughtfully, carbon calculation platforms can help site teams deliver — with transparency, accountability, and genuine care for the planet.

To find out more, click the link below.

Did you find this article helpful?

Please rate this article

Loading...