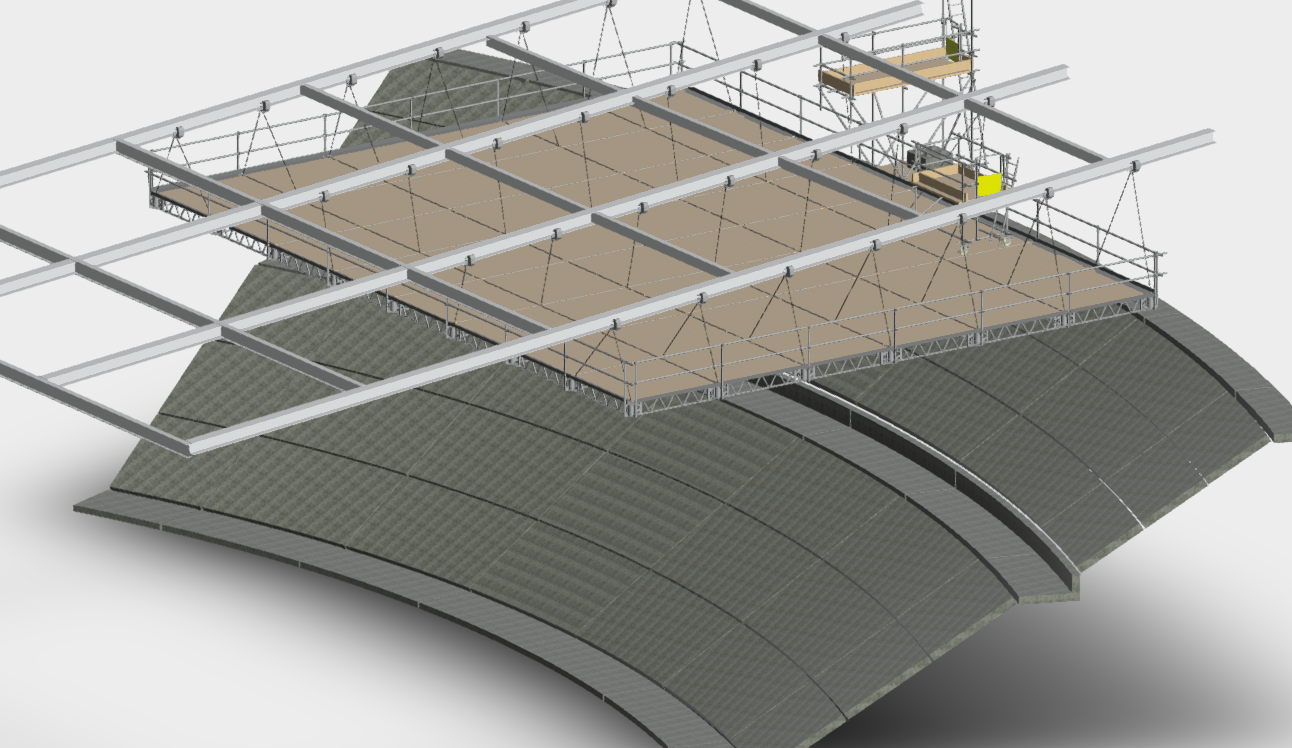

In order to allow works to the theatre roof alongside works to the auditorium below, it was proposed to install a hanging platform to provide a safe working platform for the works, whilst protecting operatives below from falling objects.

A traditional tube and fitting platform is made up of long span beams tied together with traditional tube and fitting components. These are substantial structures, which involve high-risk installation techniques including traversing along unfinished beams to install components at height.

Following some research and consultation with the contractor, a subdivision of their organisation offered their product, which is regularly used in infrastructure projects.

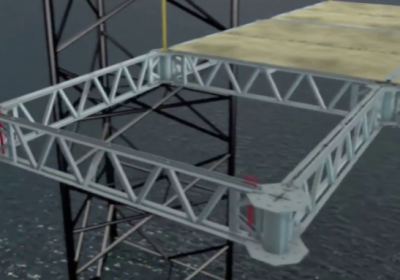

This system is Quickdeck, which is a component-based hanging platform system occasionally used in the UK for bridge soffit works. When developing the design, it became clear that the system offers some measurable advantages to a traditional solution.

There is an 80% reduction in number of components needed, resulting in;

- Considerably fewer deliveries (Impact on neighbouring properties and users)

- Less embodied Carbon due to fewer wagon hours

- Considerably reduces risk of dropped materials (a significant H&S risk with hung scaffolds)

- Reduced manual handling workload, components are easily handled by one person

There is also a 40% reduction in installation time, resulting in;

- Decreases exposure of scaffold operatives to high risk works

The specialised installation technique (Kicking out) gives the ability to build from the leading-edge resulting in 90% reduced exposure to work over open areas and removes exposure of operatives to falls whilst traversing

Did you find this article helpful?

Please rate this article

Loading...