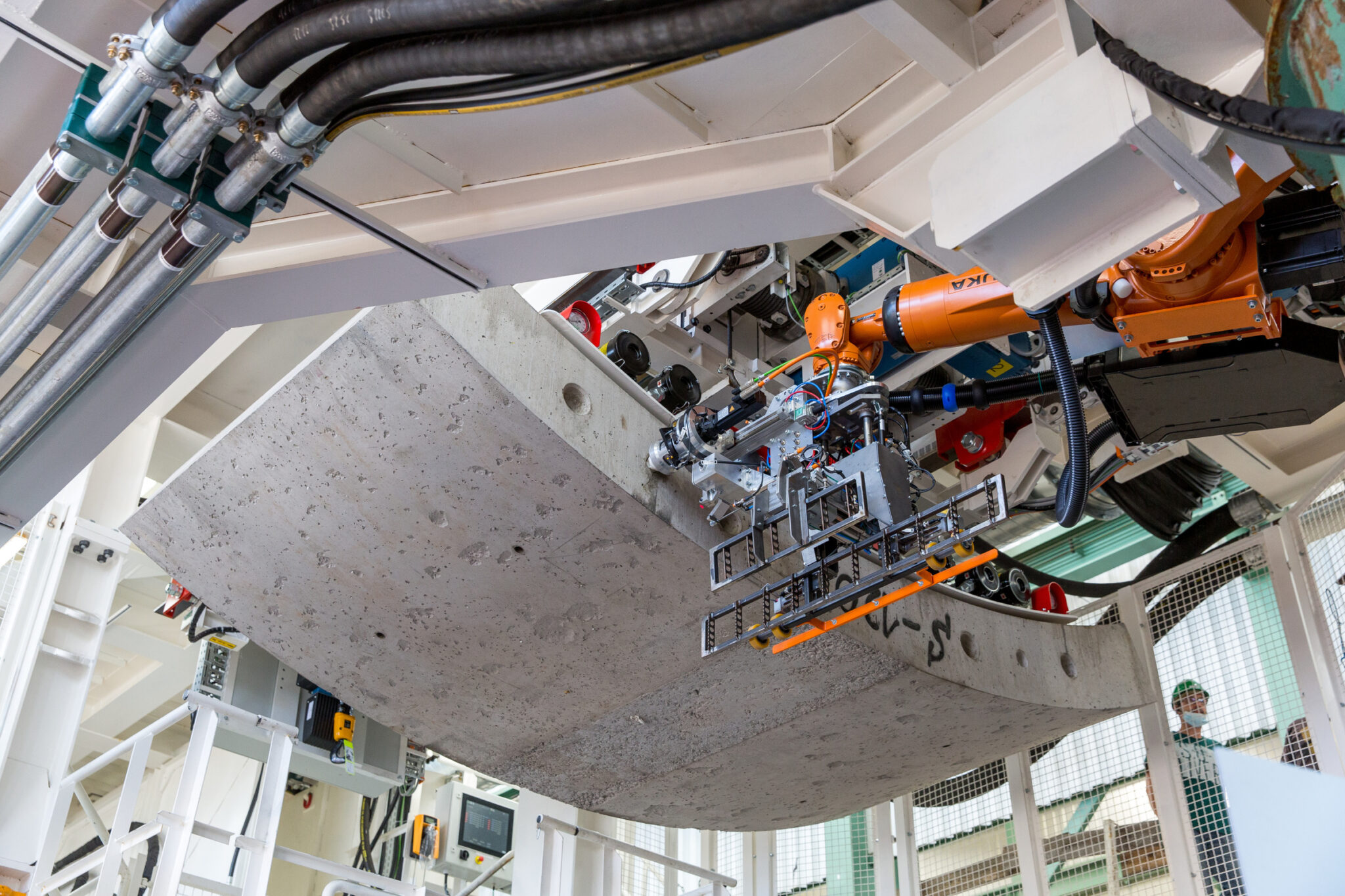

This contractor is the first in the county to use a robotic arm to perform work in the high-risk environments around the segment stacks and lift. A robotic arm performs two tasks when preparing the segments for ring building. Dobydo is the name given to the part of the robot that screws in the segment dowels and fittings.

Krokodyl is the name given to the part of the robot that collects the hardwood spacers between the segments and carries them to the storage bin for removal.

Both robotic elements remove the ergonomic burden of having to undertake this by hand, whilst also having the safety benefits of not needing workers to operate adjacent to heavy moving segments. Examples for other simple ergonomic benefits can be seen in the orientation and positioning of the pumping equipment. Knowing these will require regular access and maintenance, they have been raised to waist height and orientated through 45 degrees, enabling free and easy access to each of the six pumps.

The benefit of designing and constructing this with a clear consideration of its use as a workplace has meant that ergonomic risks are better controlled, with greater use made of lifting equipment and other controls. By removing the workers from high risk environments such as around the segment lifts and the ring build area the project has the benefit of not having incidents in these areas.

Monitor Report. Align Joint Venture. Hertfordshire. March 2023.

Did you find this article helpful?

Please rate this article

Loading...