To deliver long welded rail to site, a specialised rail fleet provided by Network rail is required. Availability of these trains is limited which was preventing efficient programming of works. An older long welded rail delivery train (LWRT) had been mothballed due to no protection to staff working at height but offered an opportunity to resolve the delivery problem.

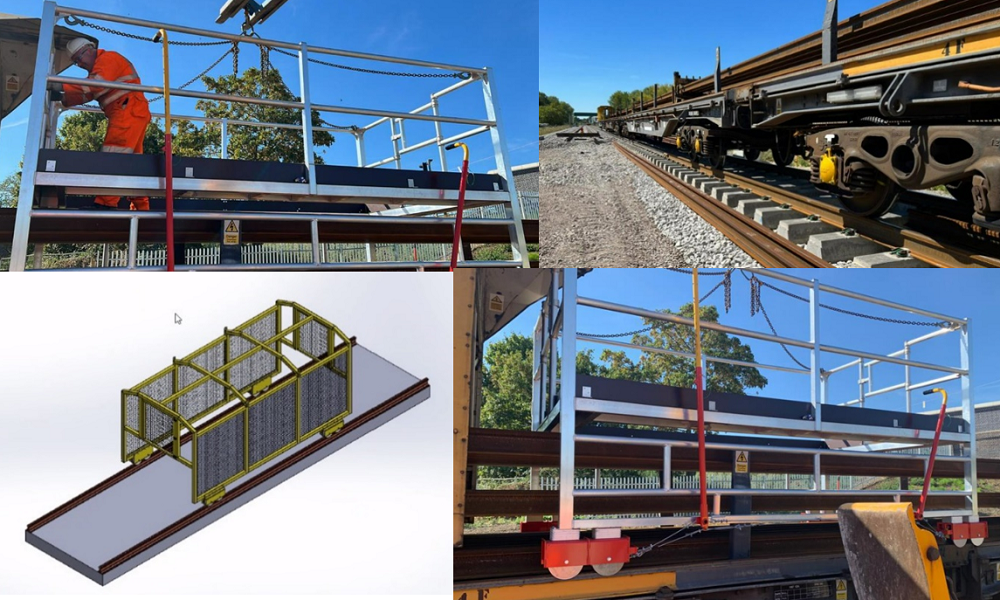

To overcome this issue and re-introduce the train a solution to the working at height risk was required. The project proposed a solution to Network Rail who through their supply chain, designed and implemented it. This allows staff to work inside a ‘fence’ mounted on wheels which can travel along the train to where it is required at the point of works.

Due to the nature of how the train operates, it was not possible to simply weld fences to the sides of the train. Therefore, the solution need to involve a system that could be mounted onto the train gantry rails and be light enough for two operatives to push along. It required the strength and stability for a person to safely operate from it.

By having the fence system moveable on the train, it meant the train could operate as it had done before, but with only a minor change to the operating procedure. The ‘trolley’ is lifted onto the train by a telehandler at the start of the shift, then removed again before the train leaves the worksite.

Monitor Report. EWR Alliance. Oxfordshire. September 2022.

Did you find this article helpful?

Please rate this article

Loading...