Spotlight on… carbon reduction asks what net zero means for the industry and outlines easy and practical guidance to support your decarbonisation journey.

carbon reduction

Reducing our carbon emissions has become one of the biggest issues for our generation. In this ‘Spotlight on…’ we ask what net zero means for the industry and outline easy and practical guidance to support your decarbonisation journey.

Introduction

Climate change and global warming has become one of the single largest threats to our planet and having dominated our headlines for decades, it is the defining issue of a generation. Many governments have declared a climate emergency, with more than 70 countries including the UK and Ireland, pledging their commitment to become net zero by 2050 as part of the landmark Paris Agreement. With energy consumption and carbon (CO2) emissions in the construction industry reaching an all-time high, how is the sector adapting to meet these legally-binding targets? In this ‘Spotlight on…’ we ask what net zero means for the industry and outline easy and practical guidance to support your decarbonisation journey.

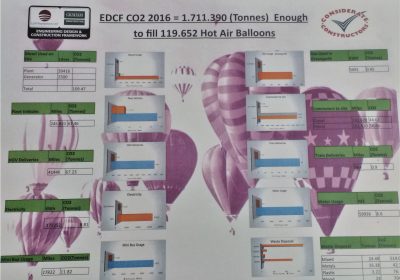

The UK and Ireland construction industry is responsible for 25% of our total carbon footprint, generating 40 – 50 million tonnes of CO2 emissions annually. To put this into perspective, this is more than the total emissions from aviation and shipping combined. According to a recent survey conducted by the Considerate Constructors Scheme to more than 450 construction industry professionals, over 90% of respondents believe there is an issue with the amount of CO2 emissions produced by construction, with energy and fuel consumption seen as the main contributor. 83% of respondents believe the industry has the potential to significantly reduce its CO2 emissions, with over 60% feeling the sector is not doing enough to tackle the issue.

The outlook is even worse from a global perspective with the building and construction sector accounting for over 34% of energy consumption and 37% of CO2 emissions. With demand for raw materials predicted to double by 2060 (including some of the biggest contributors to CO2 emissions), and growing population and commercial demands putting increasing pressure on the industry, is it possible to make a difference to reduce CO2? What guidance is there to decarbonise and fulfil the Government’s commitment to become net zero by 2050, and how do we pave the way for greener, cleaner and more sustainable practices in construction.

What are the typical sources of CO2 emissions in construction?

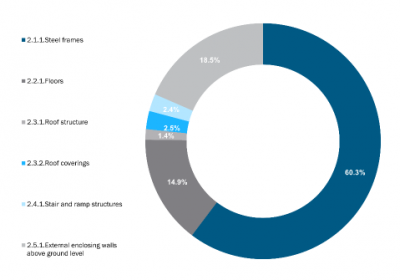

From the mining and manufacturing of materials such as concrete and cement, to the management and eventual deconstruction of a structure, CO2 emissions can be found at every stage of a construction and engineering lifecycle.

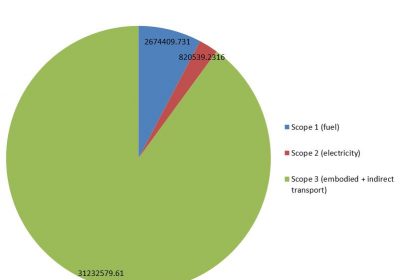

The Greenhouse Gas Protocol framework provides a globally recognised classification to group sources of CO2 emissions at an organisational level.

Typical sources of CO2 emissions in construction are split into three scopes and include:

| Scope 1 (direct): | Emissions caused by an organisation directly; for example from running machinery and heating buildings. |

|

| Scope 2 (indirect): | Emissions generated indirectly when energy is produced on behalf of the organisation from a utility provider. |

|

| Scope 3 (indirect): | Emissions produced from the supply chain and at a customer level. |

|

What are carbon emissions and why does it matter?

Carbon emissions, often referred to as greenhouse gases, are generated by the release of CO2. Methane and others into the atmosphere. They are created by human activity, such as the burning of fossil fuels (coal, oil and gas), the impact of deforestation and the growth in landfill and waste disposal. CO2 radiates and traps heat from the sun and this has caused our planet to warm by +1.1°C in 200 years, disturbing the natural balance of our planet and resulting in an unprecedented change to the climate.

- Higher temperatures have increased heat-related illness and the spread of disease, damaged natural habitats through increased threat of wildfires, and reduced the earth’s ability to cool down by melting the polar ice caps.

- Increased severity of storms which have become more frequent, devastating the lives of millions of people, destroying homes and communities, and causing huge economic loss.

- Drought and scarcity of water which has threatened and destroyed crops, decreasing food supply and increasing the plight of communities who struggle for water.

- Rising sea levels, hotter and more acidic oceans threatening coastal and island communities, endangering marine life and coral reefs.

- Declining biodiversity where forest fires and extreme weather conditions have increased the prevalence of disease and threatened approximately one million species with extinction in the next few decades.

- Shortage of food as climate change has compromised the yield of fisheries, crops, and livestock causing a rise in hunger and poor nutrition.

- Increased health risks as air pollution, disease, extreme weather and forced population displacement has affected the mental and physical wellbeing of around 13 million people every year.

- Poverty and displacement as extreme floods and water scarcity have forced millions of people to become refugees and into poverty.

What is the construction industry doing to tackle the problem?

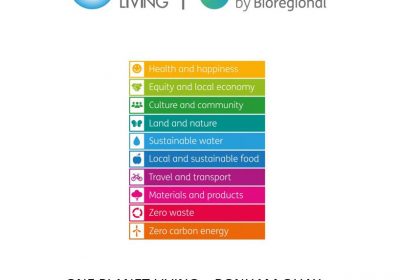

In the last decade there has been a surge in the number of resources and initiatives available to support greener practices in construction; the UK Green Building Council has published Net Zero Carbon Buildings: A Framework Definition, with principles to achieve net zero carbon. They have also created a Whole Life Carbon Roadmap which shows how industry can get to net zero by 2050. The Construction Leadership Council have launched several initiatives to champion sustainability including: CO2nstructZero, a zero carbon programme identifying nine priorities for carbon reduction that align with the government’s 10-point plan, and a Zero Avoidable Waste Routemap to help manage construction waste and reduce landfill. Part Z is an industry-proposed amendment to UK Building Regulations 2010 which would ensure that embodied carbon is assessed on all projects, as part of a comprehensive whole life carbon assessment.

BREEAM continues to influence greener more sustainable practices and is recognised by investors and contractors alike. In recent research conducted by the Scheme two thirds of respondents have worked on BREEAM or LEED certified projects. Similarly, many contractors have adopted the globally recognised ISO 14001 Certification in Environmental Management Systems to strengthen and audit environmental policies.

The project has begun to create the UK’s first Net Zero Carbon Buildings Standard which will be launching later this year to provide standardised metrics to demonstrate and verify net zero carbon buildings in the UK. Bringing together leading industry organisations including BBP, BRE, The Carbon Trust, CIBSE, IStructE, LETI, RIBA, RICS, and UKGBC, this is the first major collective step in supporting stakeholders throughout the decarbonisation of procurement, design, construction and operation of buildings. There is a suite of European Standards that cover sustainability works for construction and infrastructure. These include methodologies for assessment of environmental performance (including carbon) at a building and product level.

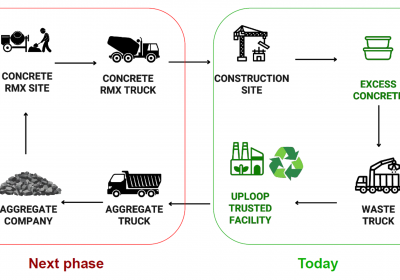

Net zero targets have been a catalyst for innovation as investment in the research and development of sustainable greener construction materials grows. Contractors are exploring new uses for existing materials such as bamboo and evaluating new resources like sustainable low carbon concrete and production methods like 3D printing in reducing emissions from production, packaging and transport. Closed loop remanufacturing schemes are emerging, creating a circular economy by re-using products and transforming them into eco-friendly new materials. Furthermore, there’s been a growth in the uptake of recycled plastics and metals, reducing waste and landfill. Manufacturers are now producing Environmental Product Declaration’s (EPD) to provide the environmental performance of a product. These are then used in whole life carbon assessment tools to assess which materials may have less of a carbon impact.

What are we doing to help support carbon reduction?

At the Considerate Constructors Scheme we prioritise the issues that affect our planet, championing sustainability, decarbonisation and the natural environment as one of the three pillars of our Code of Considerate Practice. We recognise the construction industry will need to play a significant role in helping achieve Net Zero by 2050 and are spearheading industry standards to help constructors minimise the impact of their operations, take considered steps to safeguard the natural environment and optimise the use of resources.

Our Scheme Monitors uphold standards and measure progress with Registered Activity, benchmarking initiatives and offering advice and guidance.

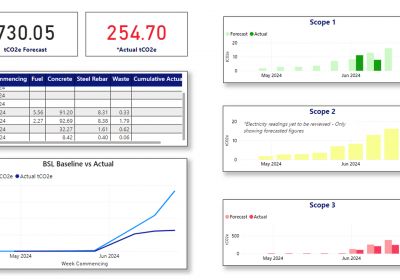

- Q2.2.1: How is the Registered Activity planning to reduce its carbon footprint, including measurement, recording and publication of performance?

- Q2.2.2: How is the Registered Activity optimising the use of resources, energy and waste?

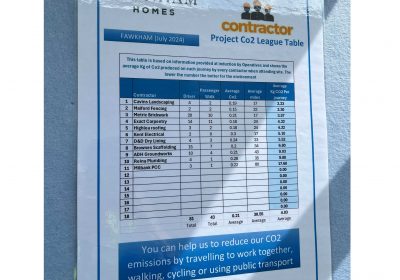

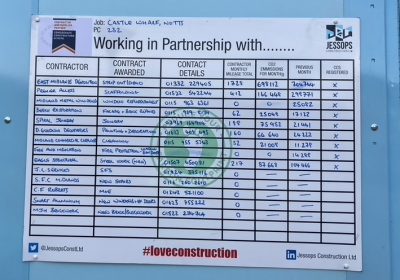

- Q2.2.3: How is the Registered Activity ensuring supply chain involvement in the reduction of carbon?

The Checklist also asks Registered Activity to optimise the use of resources, including minimising carbon throughout the value chain.

Law and legislation

Click for more

External resources

Click for more

Examples of best practice

Click for more

Case studies

Click for more

What can you do?

Whether you are a contractor, supplier, manager or construction professional, we all have a duty to protect our planet and there are lots of ways you can make a difference to build a greener, sustainable industry.

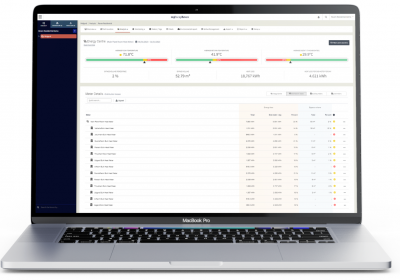

The first step to reducing CO2 emissions is to identify possible causes from a company and project level. The Greenhouse Gas Protocol framework as mentioned above is a useful tool to categorise, track and report on emissions and find opportunities to support a long-term carbon reduction strategy.

To help achieve net zero targets, education, awareness and advocacy is critical. Once a strategy, tactical plan and targets have been set, ensure it is communicated across the company or project and regularly reported on. Create a benchmark of success and celebrate achievements to inspire other teams in the business and across the supply chain. Drive change by increasing the skills and knowledge of staff through regular training and during site inductions, challenge traditional behaviours, and raise awareness with poster campaigns, toolkits and site events. Appoint advocates and champions of sustainability from the boardroom and throughout the business to promote best practice.

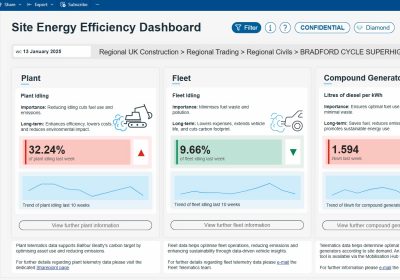

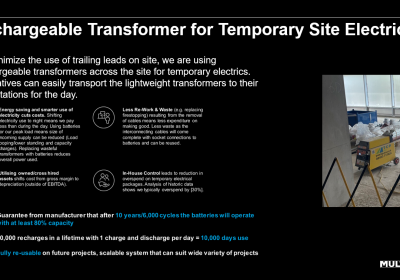

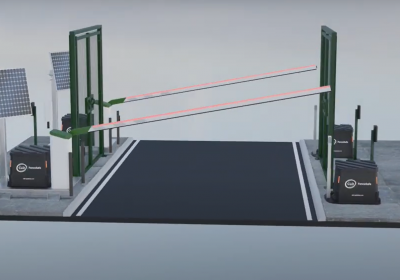

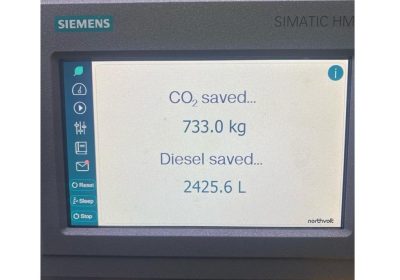

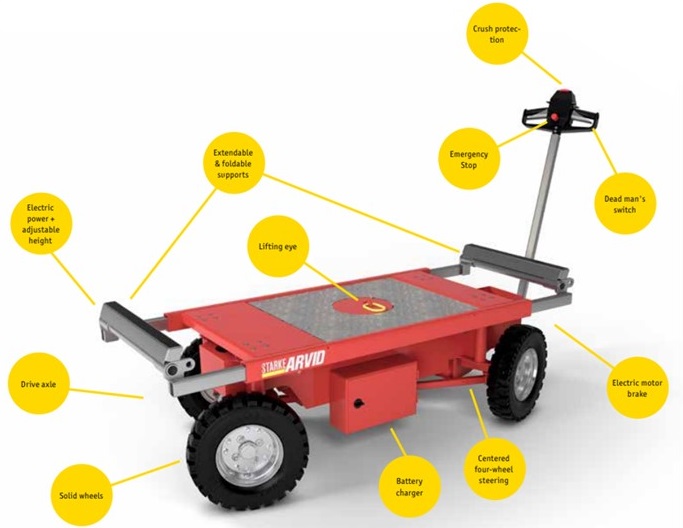

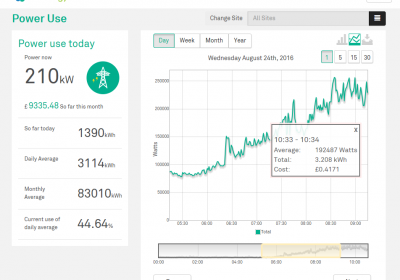

One of the biggest ways to reduce CO2 emissions is to identify, monitor and evaluate the energy used onsite; from vehicles, machinery and equipment, to lighting, heating and site accommodation. Make positive eco-conscious choices: Construction, demolition and excavation accounted for almost two thirds of the UK’s total waste. Reducing waste using the 3 R’s of waste management – reduce, reuse, recycle can make significant strides in reducing landfill and CO2 emissions. Decarbonisation is a collective responsibility and every part of the construction industry has a part to play. With an average of 50-70 suppliers on a typical project, the supply chain is a big component of a carbon zero strategy. Adopt a green supply chain management approach, integrating environmental processes and ensure you have transparency of practices. Support suppliers with guidance, best practice and share training resources. The Government’s commitment to achieve net zero by 2050 is an ambitious target and reaffirms the urgency needed to react. But in an industry that is still producing more CO2 than ever before, greater strides are needed to make an impact and tackle the issue head on. According to the Scheme’s Carbon Reduction survey 2023, over half of respondents have never worked on a project that has successfully met a CO2 reduction target, and only 1 in 3 construction projects have used renewable energy on site. Over 85% of respondents agree there is not enough incentive for construction companies to reduce their CO2 emissions, with cost seen as the biggest barrier, and smaller firms struggling to remain competitive with more expensive greener alternatives. The Construction Industry Training Board (CITB) predict the construction industry will require 350,000 new roles to be created by 2028, to ensure the government’s commitment to achieving net zero by 2050 is on track. These stark statistics suggest more work is needed to support a carbon free industry, a collective drive from contractors, designers, asset owners, manufacturers, industry bodies and across the supply chain, as well as at a policy and government level to promote investment in greener cost efficient initiatives. The opportunity to transform the industry is huge; to develop low carbon materials, zero emission plant, sustainable practices and a new generation of eco-conscious champions to lay the foundations of a sustainable greener construction industry, we can all be proud of. Further reading on this topic can be found in the References and Useful Resources section. Date published: May 25 2023 Supported by:

Conclusion

Last updated: February 3 2025